German auto parts company Mahle has announced that it is developing a magnetless electric motor that does not require rare-earth elements. Rare-earths are composed of 17 chemical elements, including scandium (Sc), yttrium (Y) and 15 lanthanides: lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb) and lutetium (Lu).

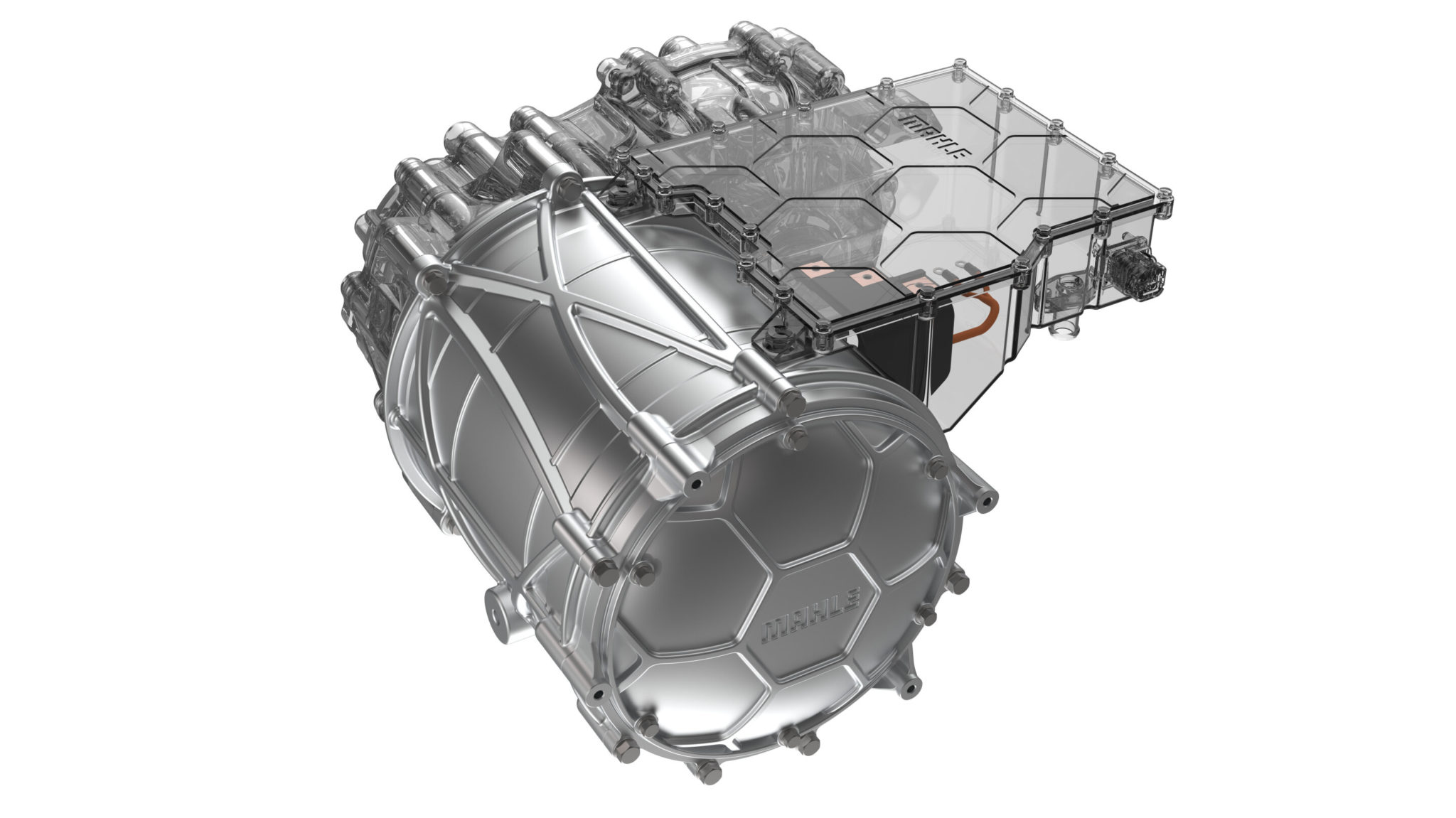

Company representatives report that the new engine is efficient and extremely durable.

As many major automakers begin switching from gasoline-powered vehicles to those that run on electric motors, the issue of rare-earth metals has taken on added urgency – China produces approximately 90 percent of the rare-earth metals used in electric motors, and China is the only country that currently has the processing capacity to handle them in large quantities. This situation has forced car makers around the world to trust Chinese suppliers, which has them worried.

In response, automakers and others have started looking to develop electric motors that don't need magnets, which means they won't need rare-earth metals. Most of those developed so far have relied on rotating contact devices that transfer electricity to copper coils in a rotor. Mahle's team's new engine eliminated these contacts, making the engine more efficient and durable as it removed one of the stress points. Instead, the new motor uses energized coils in its rotor, transferring energy to the rotating rotors by induction, which means they never have to touch and the motor has no surfaces that wear out.

Mahle officials note that the engine will be less expensive to produce without the rare earth metals. They also note that the design allows them to adjust and change rotor parameters, which in turn allows for improved efficiency. During testing, they found the design to be 95% efficient, which they note has so far only been achieved by Formula E racing cars. They even note that increased efficiency can be achieved at different speeds, which would help the car batteries to last longer. They expect mass production of the new engine to begin in approximately two and a half years, which suggests the company has already formed a partnership with an as-yet-unknown automaker.

Did you like this content? Share on your friends networks!

Source: Engenharia é